SPD Conveyor Idler Roller, Conveyor Steel Roller, Conveyor RollerDescription:  SPD Products details: SPD Germany Conveyor Idler Roller, Conveyor Steel Roller, Conveyor Roller details: Main Features of SPD Germany Conveyor Idler Roller, Conveyor Steel Roller, Conveyor Roller About Rizhao Port Machine Engineering Co., LtdCo., Ltd RZPMCis a comprehensive enterprise which engages in design, manufacture, installation and maintenance of the bulk-handling equipments. It is the wholly-owned subsidiary of the listed governmental company Rizhao port Co., Ltd. It has the Second-level Qualification of the Machinery & Electrical Equipments installation Enterprise.Â

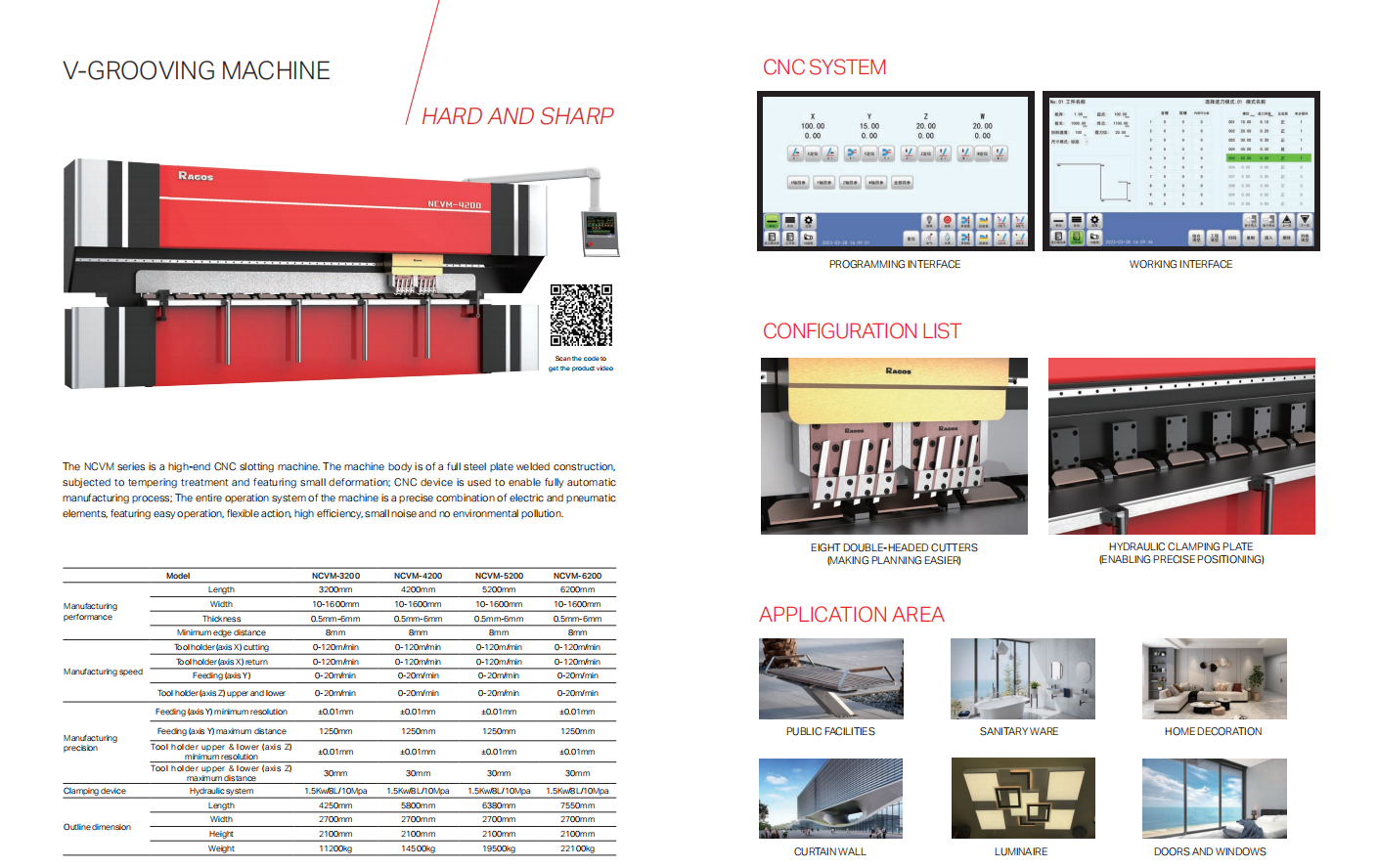

A V-grooving machine is a specialized tool used to create V-shaped grooves or cuts on various materials such as metal, wood, plastic, and even glass. The machine works by using a rotating blade that cuts into the material at a specific angle, creating a V-shaped groove. The depth and width of the groove can be adjusted according to the specific requirements of the project. V-grooving machines are commonly used in industries such as woodworking, metalworking, and signage manufacturing. They are also used in the production of architectural elements such as decorative panels, doors, and windows.

V-Grooving Machine,V-Shape Grooving Machine,High Speed Cnc V-Groove Cutting Machine,High Accuracy V-Grooving Machine FOSHAN RAGOS NC EQUIPMENT CO.,LTD. , https://www.ragosnc.com

SPD-Aligning roller set for Germany market

SPD Conveyor Roller SetComponents & Installation Details:

SPD Conveyor Roller Construction or according to your requirements:

Â

1. Brand: SPD

2. Lift time: 30000-50000 hours

3. Production capacity: as usual 600 pieces/day.

4. Roller Diameter: 76-219 mm.

5. Roller Length: 190 mm to 3500 mm.

6. Roller tube: Q235 carbon steel, high-precision ERW, welded with DIN2394 Standard

7. Shaft: Q235 carbon steel in accordance with DIN17100 and other equivalent standard, ISO h6 precision.

8. Bearing: Deep groove ball bearing 2RZ and 2Z with C3 clearance.

9. Bearing brand: SKF, FAG, NSK, LYC etc.

10. Seals: Grease retaining inner seal with multi-stage labyrinth and retention cap with outboard rubbing flinger seal.

11. Color: according to your requirement.

12. Finish: Ordinary painting / Rubber / Steel screw / Galvanized.

13. Welding: Mixed gas shielded arc welding end.

14. Professional designing and inspection team.

15. Standard: ISO / CEMA / Australia / BS / JIS / DIN.

16. Package: Export standard plywood cases with waterproofing film.

Standard Diameter

Length scope (mm)

Bearings Type

(Min~Max)Idler's Shell Wall Thickness

mm

Inch

63.5

2 1/2

150~3500

204

3.0mm~3.75mm

76

3

150~3500

204 205

3.0mm~4.0mm

89

3 1/3

150~3500

204 205

3.0mm~4.0mm

102

4

150~3500

204 205 305

3.5mm~4.0mm

108

4 1/4

150~3500

204 205 305 306

3.5mm~4.0mm

114

4 1/2

150~3500

205 206 305 306

3.5mm~4.5mm

127

5

150~3500

204 205 305 306

3.5mm~4.5mm

133

5 1/4

150~3500

205 206 207 305 306

3.5mm~4.5mm

140

5 1/2

150~3500

205 206 207 305 306

3.5mm~4.5mm

152

6

150~3500

205 206 207 305 306 307 308

4.0mm~4.5mm

159

6 1/4

150~3500

205 206 207 305 306 307 308

4.0mm~4.5mm

165

6 1/2

150~3500

207 305 306 307 308

4.5mm~6.0mm

177.8

7

150~3500

207 306 307 308 309

4.5mm~6.0mm

190.7

7 1/2

150~3500

207 306 307 308 309

4.5mm~6.0mm

194

7 5/8

150~3500

207 307 308 309 310

4.5mm~6.0mm

219

8 5/8

150~3500

308 309 310

4.5mm~6.0mm

SPD Wood Chips Belt Conveyor Projects Installation on the site

SPD Conveyor Roller Certificate & Customers' Visit

Main Facilities & Capabilities

Cutting equipment:Â

Numerical control cutter machine, semi-manual cutter machines.Â

Forming equipment:Â

300T friction punching machine, 160T punching machine, mechanical plate shearing machine.Â

Plate roll equipment:Â

Hydraulic four rolls plate roll equipment, mechanical three rolls plate roll equipment.Â

Welding equipment:Â

Union melt welding, argon arc welding machine, carbon dioxide protection welding machine, AC arc welding machine, direct current arc welding machine.Â

Test and Measure Instruments: Paint Film Thickness Gauge, Buluowei hardness machine, Theodolite Magnetic Particle Flaw Detector, Metal gage, Ultrasonic Flaw Detector.Â

Heat treatment: Electric furnace, carburizing furnace.Â

Paint shop facilities: Pneumatic paint shop facility, high-pressure paint shop facility.Â

Packing and Shipping:Â

Â

SPD famous Conveyor Roller brand, 301 - 500 workers, 25000 m³ non-dust workshop, Registered Capital: RMB 69,000,000, 20 years experience, 35 Engineers and technicians, 28 Professional designers, 7 Senior engineers, 18 engineers, two hours to Qingdao port.

Samples are acceptable. Rush order and large quantity are acceptable.Â

We begin to make belt conveyor from the year 1993, and has lots of large contracts of manufactures and installation projects, widely used in ports, mining, food, power plants and other industries.Â

Our steel structures and frames production capacity is 160,000 tons/year, the main products are belt conveyor, stacker-reclaimer machine, car loader machine, un-loader machine, etc. In the year of 2005, we rely on our own technological superiority, self-design and manufacture the storage capacity of 9000 T/H of the stocker, as a national origin.

Â

BrandÂ

SPDÂ

SpecificationÂ

SPD-Aligning roller setÂ

Certificate

ISO/BV/SGS

Standard

CEMA/JIS/DIN/Australia

Application

Coal mining industry, cement, steel, harbour etc. Â

Place of OriginÂ

Rizhao City , Shandong Province , China

Material Feature

Water, Wear, Dust resistanceÂ

Supply capacityÂ

600pcs/day

Management systemÂ

ISO 9001:2008, ISO 14001:2004, GB/T 28001-2001

SPD Germany Conveyor Idler Roller, Conveyor Steel Roller, Conveyor Roller

Model NO.: SPD-Aligning roller set

Roller Diameter: 76-219mm

Roller Length: 190mm to 3500mm

Roller Tube: Q235 Carbon Steel

Shaft: Q235 Carbon Steel

Bearing: Single and Double Row Deep Groove Ball Bearing 2rz

Bearing Brand: SKF, NSK, Lyc etc.

Finish: Painting/Rubber/Steel Screew/Galvanized

Welding: Mixed Gas Shielded Arc Welding End

Trademark: SPD

Transport Package: Standard Export Plywood Cases

Specification: SPD-Aligning roller set

Origin: Rizhao City, Shandong Province, China

HS Code: 84313900

Our roller range:

Carrying roller, return roller, impact roller, vertical roller, self-alignment roller, side roller, through roller, roller group, etc.