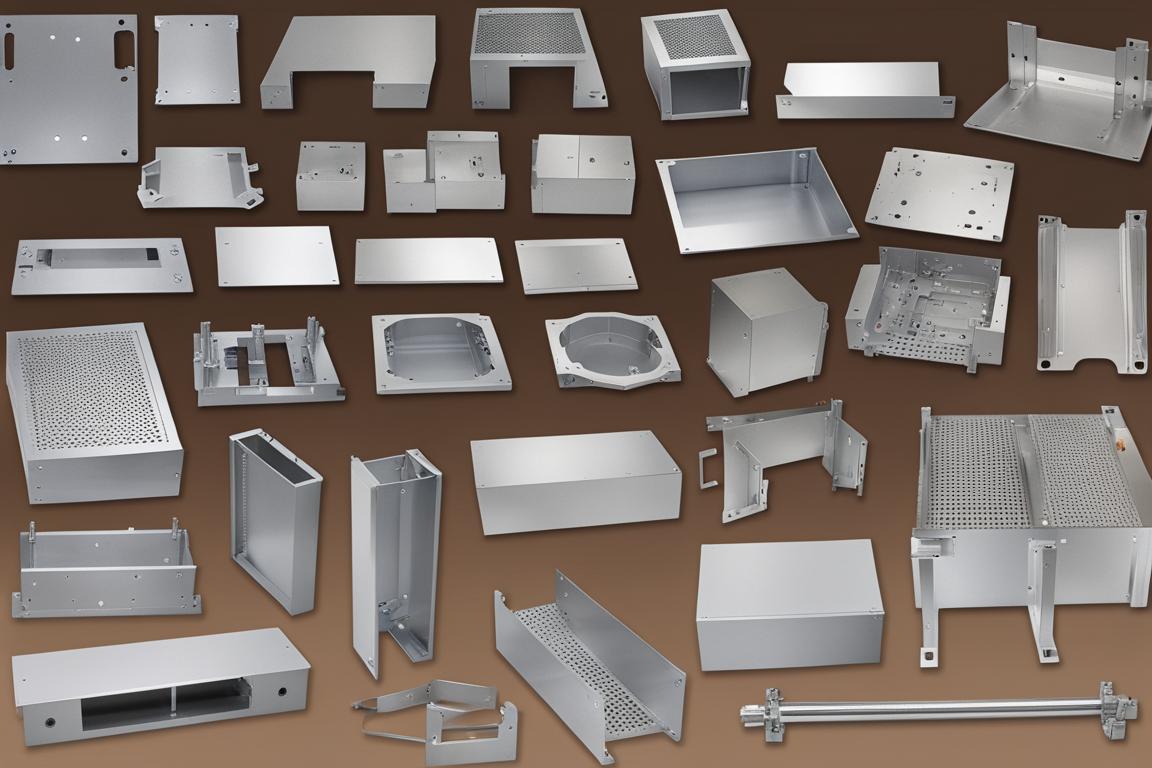

In the world of electronics, the performance and longevity of devices depend heavily on proper protection. Electronic enclosures serve as the first line of defense, shielding sensitive components from dust, moisture, mechanical stress, and environmental hazards. These enclosures are not just about aesthetics—they play a key role in maintaining device functionality, ensuring structural integrity, and managing heat dissipation for optimal operation. Electronic enclosures—also known as cases or chassis—are protective housings designed to contain and protect electronic components. They come in a wide range of sizes and shapes, tailored to fit everything from small handheld devices to large industrial systems. Typically made from metals like steel or aluminum, or composite materials, these enclosures are built to last, offering both physical protection and environmental resistance. The main purpose of an electronic enclosure is to protect internal components from external threats such as humidity, temperature fluctuations, and physical damage. By enclosing devices in a controlled environment, manufacturers ensure consistent performance and reduce the risk of failure. Additionally, enclosures help manage electromagnetic interference (EMI) and radio frequency interference (RFI), which can disrupt signal quality and cause malfunctions in sensitive equipment. Precision sheet metal fabrication is at the heart of creating reliable and high-performance electronic enclosures. This process involves cutting, bending, and assembling metal sheets with exact specifications, ensuring that each component fits perfectly and meets industry requirements. The result is enclosures that are not only strong and durable but also aesthetically pleasing and functionally superior. When it comes to sheet metal enclosures, precision is everything. Accurate manufacturing ensures that there are no gaps or misalignments, which could lead to poor performance or even failure. It also allows for more complex designs and custom features, making it possible to create enclosures that are tailored to specific applications. This level of detail contributes to better heat management, improved durability, and enhanced overall device reliability. The quality of precision sheet metal fabrication has a direct impact on the lifespan and performance of enclosures. Well-made enclosures resist corrosion, deformation, and wear, ensuring that the devices inside remain protected over time. Moreover, precise fabrication techniques enhance thermal management, helping devices operate efficiently even under demanding conditions. There are several types of enclosures used in the industry, each designed for specific applications. Common examples include rack-mount enclosures, junction boxes, handheld enclosures, and wall-mounted enclosures. Each type is engineered to meet the unique needs of the devices they protect, whether it's for data centers, industrial environments, or portable electronics. To strengthen the credibility of this article, including real-world case studies or client testimonials would be beneficial. Additionally, mentioning the qualifications of the author or experts consulted, along with references to industry reports or certifications, would add more depth and trustworthiness to the content. Some leading companies in this field include ABC Enclosures and XYZ Fabrication, known for their high-quality, custom-designed enclosures. These manufacturers typically provide services such as custom design, laser cutting, bending, welding, and surface finishing to meet client needs. You can contact them through their official websites, use online contact forms, or reach out directly via phone or email. They specialize in delivering high-quality, customized solutions that are tailored to the specific requirements of their clients. Project timelines vary depending on complexity, but most projects take between a few weeks to a couple of months. While costs may vary, many manufacturers offer competitive pricing for their specialized and high-quality services. Plasma Zinc And Aluminum Deburring Machine Plasma Zinc And Aluminum Deburring Machine,Zinc-Aluminum Deburring Machine,Aluminum Deburring Machine,Automatic Zinc Alloy Deburring Machine Dongguan Bayi Automation Equipment Co., Ltd , https://www.bayipolisher.com

Discover the Role of Enclosure Manufacturers in Precision Sheet Metal Fabrication

What Are Electronic Enclosures and Why Do They Matter?

Why Enclosures Are Essential for Electronic Devices

The Importance of Precision Sheet Metal Fabrication in Enclosure Manufacturing

How Precision Affects Quality and Performance

Impact on Longevity and Functionality

Common Types of Enclosures in Precision Sheet Metal Fabrication

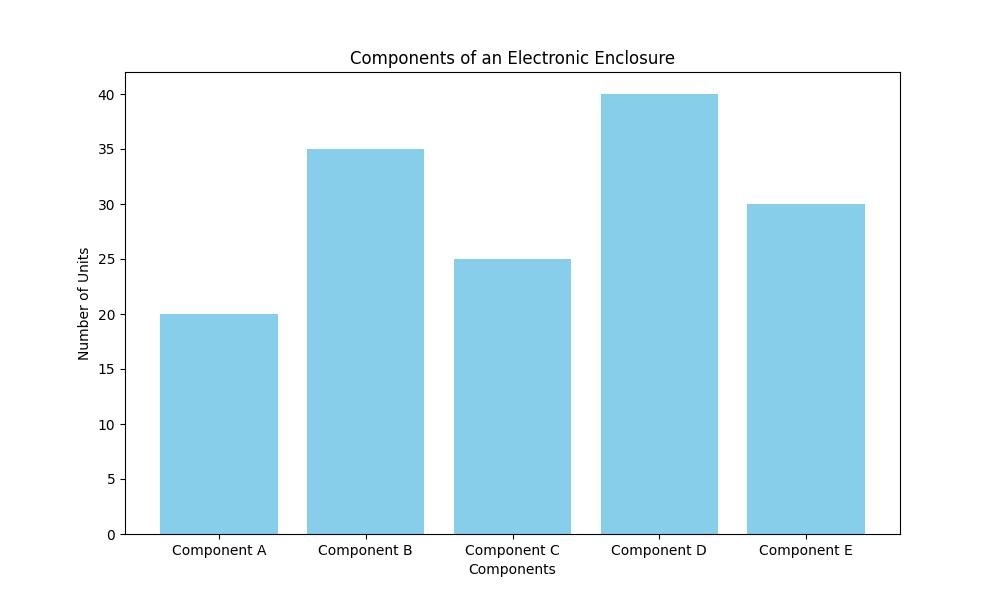

Key Features of Different Enclosure Types

Enclosure Type

Function

Rack-Mount Enclosures

Designed for server and networking equipment in data centers and IT infrastructure.

Junction Boxes

Used to protect electrical connections and wiring in industrial and commercial settings.

Handheld Enclosures

Engineered for portable devices like remote controls, scanners, and medical instruments.

Wall-Mount Enclosures

Offer space-saving solutions for control panels, security systems, and monitoring equipment.

Frequently Asked Questions

Who are the top enclosure manufacturers in precision sheet metal fabrication?

What services do precision sheet metal enclosure manufacturers offer?

How can I request a quote from them?

What makes precision sheet metal enclosure manufacturers stand out?

How long does it take to complete a project?

Are precision sheet metal enclosures expensive?