Autodesk Ups the Ante on Advanced Manufacturing with Technology Updates, New Alliances

At the Autodesk University (AU) Las Vegas event, the conference kicked off yesterday with an inspiring general session led by CEO Andrew Anagnost and a lineup of special guests. One of the highlights was a presentation on an extraordinary manufacturing research project from NASA’s Jet Propulsion Laboratory, showcasing how cutting-edge technology is shaping the future of production.

Today, I had the opportunity to co-present with Steve Hooper in a keynote that explored the latest trends in the manufacturing industry. We discussed how our Product Design & Manufacturing Collection, along with the broader Autodesk portfolio, is evolving to better serve our customers. A great example of this is WHILL, a company that has reimagined its ultra-portable mobility chair using Autodesk’s generative design tools, resulting in a lighter and more efficient product.

Looking at the bigger picture, we're seeing a clear shift toward the convergence of design and manufacturing — a trend that's not only inevitable but also highly beneficial. As our customers embrace this change, we're working hard to accelerate it. By breaking down traditional silos between designers, mechanical engineers, and manufacturing teams, we’re improving speed, cost efficiency, innovation, and overall product quality.

To further this vision, we’re excited to announce several new developments:

**What’s Next for Generative Design**

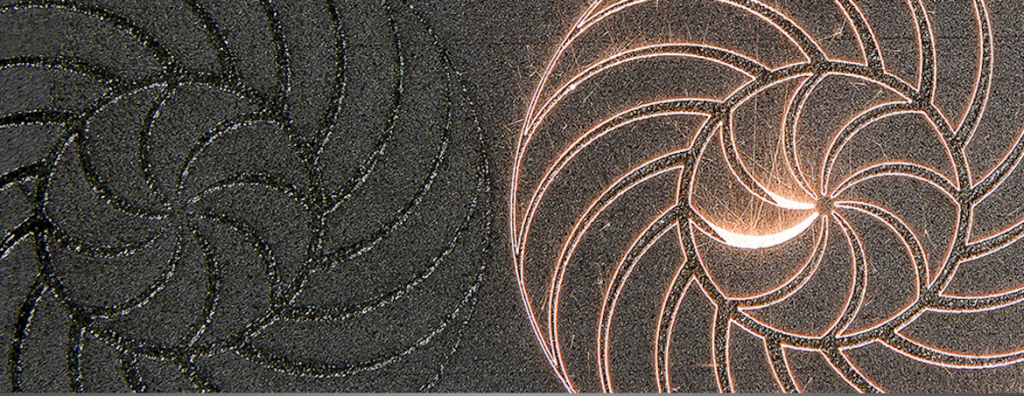

We are currently expanding the capabilities of Autodesk Generative Design to include 2- and 2.5-axis machining. This is a major step forward, as these machining methods are widely accessible through even the most affordable CNC machines. With this update, Fusion 360 users will have even more flexibility in creating optimized designs that are both functional and manufacturable.

Additionally, new subscribers to Fusion 360 will receive 100 cloud credits as a one-time grant. These credits can be used across our cloud-based services, including generative design, simulation, and CAM, ensuring you only pay for what you use.

Fusion 360 now offers a true hybrid manufacturing experience, combining advanced additive and CAM workflows into one seamless platform. For more details, check out the [Fusion 360 blog](http://bsg-i.nbxc.com/blog).

**Additive, Meet Generative**

We've developed a streamlined design-to-print workflow for additive manufacturing, integrating Autodesk Netfabb and Fusion 360 with HP Multi Jet Fusion 3D printers. This workflow makes it easier for customers to turn digital designs into physical parts quickly, accelerating the prototyping process and enabling high-quality, production-ready 3D printed components.

Penumbra Engineering recently used this workflow to create an ultrasonic sensing device for a client. Using Autodesk Generative Design and HP Jet Fusion technology, they achieved a lightweight and balanced design that meets strict performance standards while being easy to handle in the field.

Michelle Bockman, Global Head of 3D Printing Commercial Expansion & Development at HP, said: “By combining the voxel-level capabilities of HP Multi Jet Fusion with Autodesk Generative Design, we’re unlocking new levels of creativity, speed, and quality in both prototyping and production.â€

As part of this collaboration, HP and Autodesk are offering a free one-year Fusion 360 subscription with the purchase of any HP Jet Fusion 300, 500, or 4200 printer before FORMNEXT 2019, along with 300 cloud credits for those who register before January 31, 2019.

**Let the Metal Flow**

We’re also partnering with GE Additive to simplify metal additive manufacturing. The new integrated workflow, built on the Fusion 360 platform, connects all stages of the additive process — from design and simulation to printing and machine analytics.

By leveraging GE Additive’s software algorithms and data models, the workflow provides early-stage cost and timeline projections, helping designers make informed decisions without needing to produce physical prototypes first.

Lars Bruns, software leader at GE Additive, said: “This partnership will provide a powerful design-to-print environment, lowering the barriers to additive adoption and helping customers get to their first good part faster.â€

**Additive for Everyone**

Autodesk is collaborating with EWI to accelerate the adoption of additive manufacturing technologies, including Directed Energy Deposition (DED). Through training programs and educational seminars, engineers from EWI and DED equipment manufacturers are learning how to use Autodesk PowerMill 2019 and other tools to enhance their additive manufacturing capabilities.

The next phase of this partnership will involve launching a comprehensive additive manufacturing training course designed to bridge the gap between processes, software, and hardware.

From product development to industry-wide collaborations, we’re committed to pushing boundaries. All of these advancements build on the strong foundation already provided by our Product Design & Manufacturing Collection — a collection that delivers immense value far beyond the cost of an annual subscription.

Why do we do this? Because Autodesk has always been about making advanced technology accessible to everyone. We're staying true to that mission. Our goal is to help our manufacturing customers prepare for and embrace the future of making so they can succeed. And when our customers win, we all win.

We offer a range of Laser Cutting Machine accessories, including a Full range of nozzles. For example, Copper Laser Nozzle, Fiber Laser nozzle, High-speed laser nozzle and more. Or Motor as well as accessories, including some High Reliability Ceramic Ring Injetor and other products. Please feel free to contact us if there is any need.

Bystronic Glass tube

Wuxi huaoulai automation equipment Co., Ltd , https://www.china-hol.com